Technical terms, finishing techniques, complications, and engineering concepts for serious enthusiasts.

SECTION 1: ADVANCED MOVEMENT COMPONENTS

Arbor

The central shaft around which a wheel or spring barrel rotates.

Barrel Arbor

The central axle that the mainspring winds around inside the barrel.

Breguet Overcoil

A hairspring shaped with an elevated outer coil to improve isochronism (constant timing regardless of amplitude).

Cap Jewel

A flat jewel that sits above a pivot to minimise friction and improve shock resistance.

Co-Axial Escapement

Invented by George Daniels; reduces friction by separating locking and impulse functions. Used heavily by Omega.

Collet

The tiny ring securing the inner end of a hairspring to the balance staff.

Colimacon (Snail Cam)

Used in perpetual calendars and chronographs to naturally drive retrograde hands.

Column Wheel

A rotating pillar-controlled wheel that governs the start/stop/reset functions of high-end chronographs.

Endshake

The vertical play of a wheel or pivot between its jewels; critical for accuracy.

Friction Spring

A spring that maintains proper tension in mechanisms like date jumps.

Incabloc

A proprietary shock-protection system for balance wheels.

Pinion

A small gear with few teeth used to transfer motion between wheels.

Wolf's Tooth

A rare type of gear tooth with curved profiles used in high-end watchmaking.

SECTION 2: ADVANCED ESCAPEMENT & REGULATION TERMS

Beat Error

The difference in time between the tick and the tock. Ideally near zero.

Isochronism

The ability of a balance wheel to maintain the same timekeeping accuracy regardless of its amplitude.

Lift Angle

The angle through which the balance wheel travels while in contact with the pallet fork. Needed for timing calculations.

Overbanking

When the balance swings too far and the impulse pin lands outside the pallet fork—causes stoppage or erratic timing.

Poise

Balance wheel weight distribution; poising corrects imbalance to improve accuracy.

Rate

Time gained or lost per day in a specific position.

Terminal Curve

Special shaping of the hairspring ends to improve isochronism (Breguet overcoil is one example).

SECTION 3: COMPLICATIONS—ADVANCED & HIGH-END

Annual Calendar

Automatically adjusts for 30 and 31-day months; requires correction once per year (February).

Perpetual Calendar

Tracks date, day, month, leap year, and sometimes moonphase—no correction needed until year 2100.

Flying Tourbillon

A tourbillon supported only from the underside, giving the appearance of floating.

Double Tourbillon / Gyrotourbillon

Multiple axes of rotation designed to counteract gravity in all wrist positions.

Equation of Time

Shows the difference between solar time and standard (mean) time.

Minute Repeater

Strikes hours, quarters, and minutes on demand via gongs inside the case.

Monopusher Chronograph

All chronograph functions (start/stop/reset) controlled by a single pusher.

Rattrapante (Split-Seconds Chronograph)

Allows measurement of two events simultaneously by splitting the seconds hand.

Retrograde Display

Hands jump back to zero at the end of a scale instead of rotating in a full circle.

Deadbeat Seconds

A mechanical watch whose seconds hand ticks once per second like a quartz watch—rare and complex.

SECTION 4: ADVANCED FINISHING TECHNIQUES

Anglage (Beveling)

Beautifully finished chamfered edges on bridges or levers—hand-applied in haute horology.

Black Polishing (Specular Polishing)

Creates a perfectly reflective, mirror-like surface visible only from certain angles.

Côtes de Genève (Geneva Stripes)

Decorative stripes applied to bridges and plates.

Frosting

A matte grainy finish created using chemical or abrasive processes.

Perlage (Pearl Pattern)

Circular overlapping patterns often seen on inner plates.

Sunburst Finish

Radiating brushed effect, commonly used on dials.

Vertically Grained Brushing

Linear brushing pattern used on high-quality case finishing.

SECTION 5: CASE ENGINEERING & EXTERNAL COMPONENTS

Anodising

Electrochemical treatment that hardens aluminium and adds colour.

Bezel Insert

The inner ring set into a bezel—common in dive watches (ceramic, aluminium, sapphire).

Ceramic Case

Lightweight, highly scratch-resistant material; challenging to machine.

Caseback Torque

Specific pressure required to secure a screw-down caseback and maintain water resistance.

Fixed Bar Lugs

Solid steel bars instead of spring bars—favoured for military watches.

Gaskets

Rubber or silicone seals that ensure water resistance.

Helium Escape Valve

Releases built-up helium in saturation diving environments.

Internal Rotating Bezel

Operated via a secondary crown inside the case.

SECTION 6: STRAPS, BRACELETS & MATERIALS

H-Link Bracelet

A bracelet style shaped like repeating “H” links.

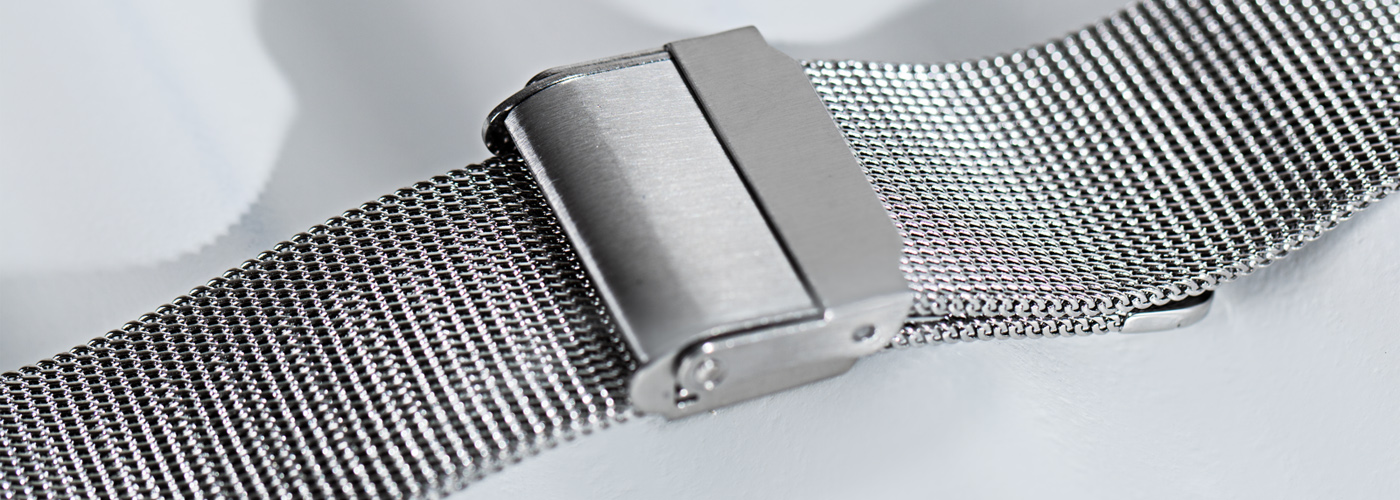

Milanese Mesh

Fine metal mesh bracelet popularised in mid-century watches.

FKM Rubber

High-performance fluorinated rubber used in premium straps.

Heat-Blued Steel

Steel heated until it turns deep blue; used for hands and screws.

Tropic Strap

Vintage-styled perforated rubber strap designed for diving.

SECTION 7: DIAL ENGINEERING & ADVANCED FEATURES

Chapter Ring

An elevated or angled ring around the dial with minute markings.

Clous de Paris (Hobnail)

A traditional textured guilloché pattern made of small pyramid shapes.

Enamel Dial (Grand Feu)

Fired at high temperatures to create a glossy, timeless dial.

Guilloché

Intricate engraved patterns made using a rose engine.

Sector Dial

Dial with concentric or radial sub-sections separated by lines.

Subdial

Smaller dial inside the main dial for seconds, chronograph, or calendar functions.

SECTION 8: TIMING, MEASUREMENT & PERFORMANCE

Chronometer Certification (COSC)

Swiss standard of accuracy; −4/+6 seconds per day.

METAS Certification

Omega’s Master Chronometer standard—tests anti-magnetism, water resistance, and accuracy.

Positional Variance

Different accuracy rates depending on watch position (crown up, dial down, etc.).

Timing Machine Readouts

Measurements like rate, amplitude, beat error, and waveform.

Vibrations

Each tick of the escapement; used to calculate BPH.

SECTION 9: WATCHMAKING & CONSTRUCTION PROCESSES

Bluing (Thermal)

Heating steel screws or hands to precise temperatures for colour.

Electroplating

Applying gold, silver, or palladium layers to components.

Lapping

Ultra-flat polishing technique used for high-end bridges.

Micro-Machining

Precision CNC work for gears, bridges, and cases.

Reaming

Enlarging or finishing holes to exact tolerances.

Tolerances

The allowable deviation in manufacturing—measured in microns in horology.

SECTION 10: COLLECTOR & INDUSTRY TERMINOLOGY

Boutique Manufacture

A small independent watchmaker producing movements in-house.

Geneva Seal

Prestigious hallmark certifying Geneva-made watches with specific finishing standards.

In-House Movement

A movement designed or manufactured entirely by the brand itself.

Limited Series / Limited Production

Small-batch manufacturing offering higher exclusivity.

Lume Plot

Small lume-filled markers on the dial or bezel.

Provenance

A watch’s ownership history—important for collectability.

Ready to start building your collection? Browse our mechanical watches now!

Learn more about MN Watches and our design philosophy here.

To see our most recent watch builds, click here.